Best Practices for Equipment Maintenance

1. Keep Comprehensive Records

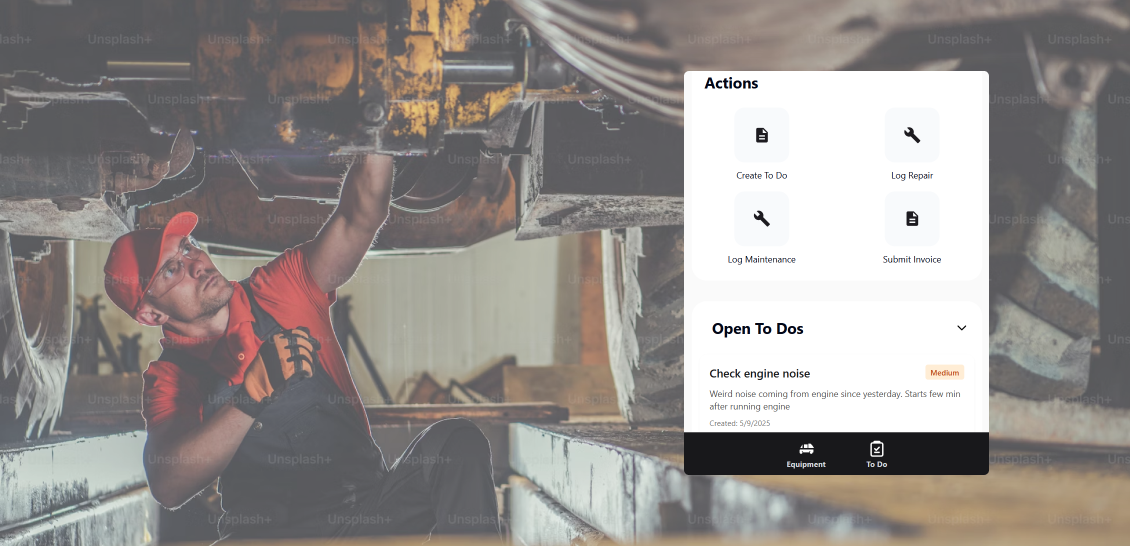

Maintain organized records of all equipment-related documents, including owner's manuals, warranties, service logs, and repair work orders. Easy access to this information streamlines maintenance tasks and provides a valuable history of each machine. With TractorLog you can keep everything in one place digitally.

2. Follow Manufacturer Guidelines for Maintenance

Follow the manufacturer's recommendations for oil change intervals and the types of lubricants to use. Proper lubrication of engines and other moving parts is essential for optimal performance and preventing premature wear. Regularly lubricate bearings, joints, and other moving components as specified. TractorLog makes this easy through setting repeat intervals for routine maintenance items.

3. Conduct Regular Inspections

Routinely inspect all equipment for any signs of damage, such as cracks, dents, or leaks. Promptly address any issues to prevent further deterioration and potential breakdowns. Pay close attention to hitches and ensure they are secure. Regularly check tire pressure, tread depth, and overall tire condition for safe and efficient operation. Inspect and test all lights, replacing faulty bulbs and ensuring batteries are in good working order for visibility and functionality.

4. Keep Equipment Clean

Regularly clean your machinery to remove dirt, debris, and crop residue. This prevents corrosion and helps maintain optimal functionality.

5. Calibrate Specialized Equipment

If you operate specialized equipment, calibrate it regularly according to the manufacturer's guidelines to maintain accuracy and optimize performance.

6. Prioritize Indoor Storage

Whenever possible, store your equipment in a sheltered, indoor space. This protects it from harsh weather conditions and can significantly extend its lifespan.

7. Avoid Modifications if Possible

Refrain from making unauthorized modifications or customizations to engines or other critical components. These alterations can void warranties and potentially harm the equipment's performance and reliability. With TractorLog, you can track any changes to your equipment.

Conclusion

By implementing these best practices, you can ensure your farm equipment operates efficiently, reliably, and for years to come. Consistent maintenance is an investment that pays dividends in reduced downtime and increased productivity.